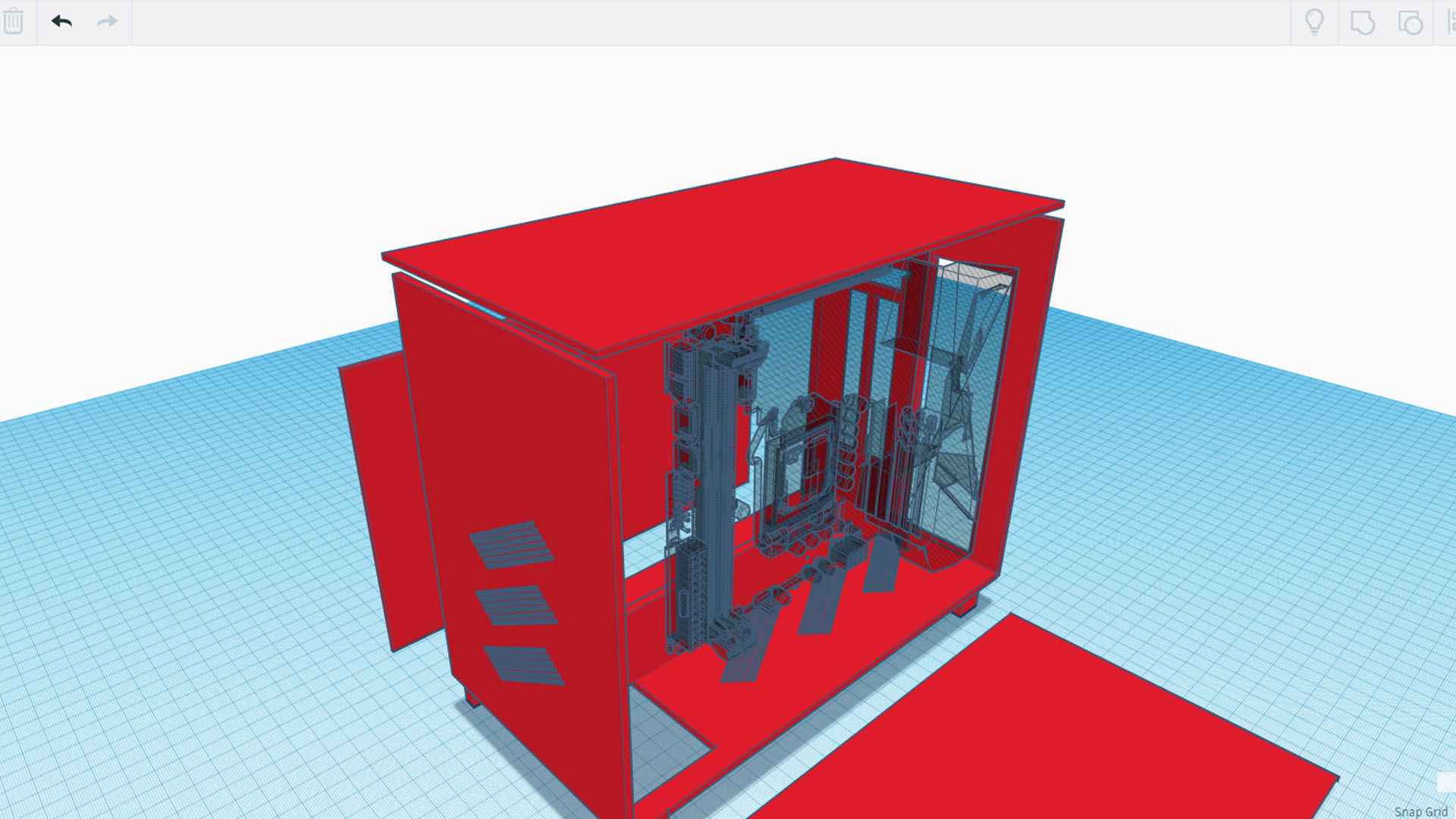

3D Printed PC Case is an innovative approach to customizing personal computer housing. This method offers flexibility in design and functionality tailored to user needs.

3D printing has revolutionized the way we think about personalization in the tech world, especially for computer enthusiasts. Crafting a PC case via 3D printing not only caters to the aesthetic preferences of the user but also allows for the incorporation of specific design requirements for cooling, form factor, and layout.

It is a versatile option that fits well within niche markets, such as custom gaming rigs or unique workstation setups. More importantly, it empowers users to break free from the constraints of mass-produced models and to create something unique. This is especially appealing to those who seek to have a PC case that stands out or meets very particular specifications that aren’t available in commercial products. With advancements in 3D printing technology, the process of creating a durable and functional PC case has become more accessible, enabling tech DIYers and hobbyists to experiment and innovate in the comfort of their own homes.

Credit: modcase.com.au

The Rise Of Custom Pc Building

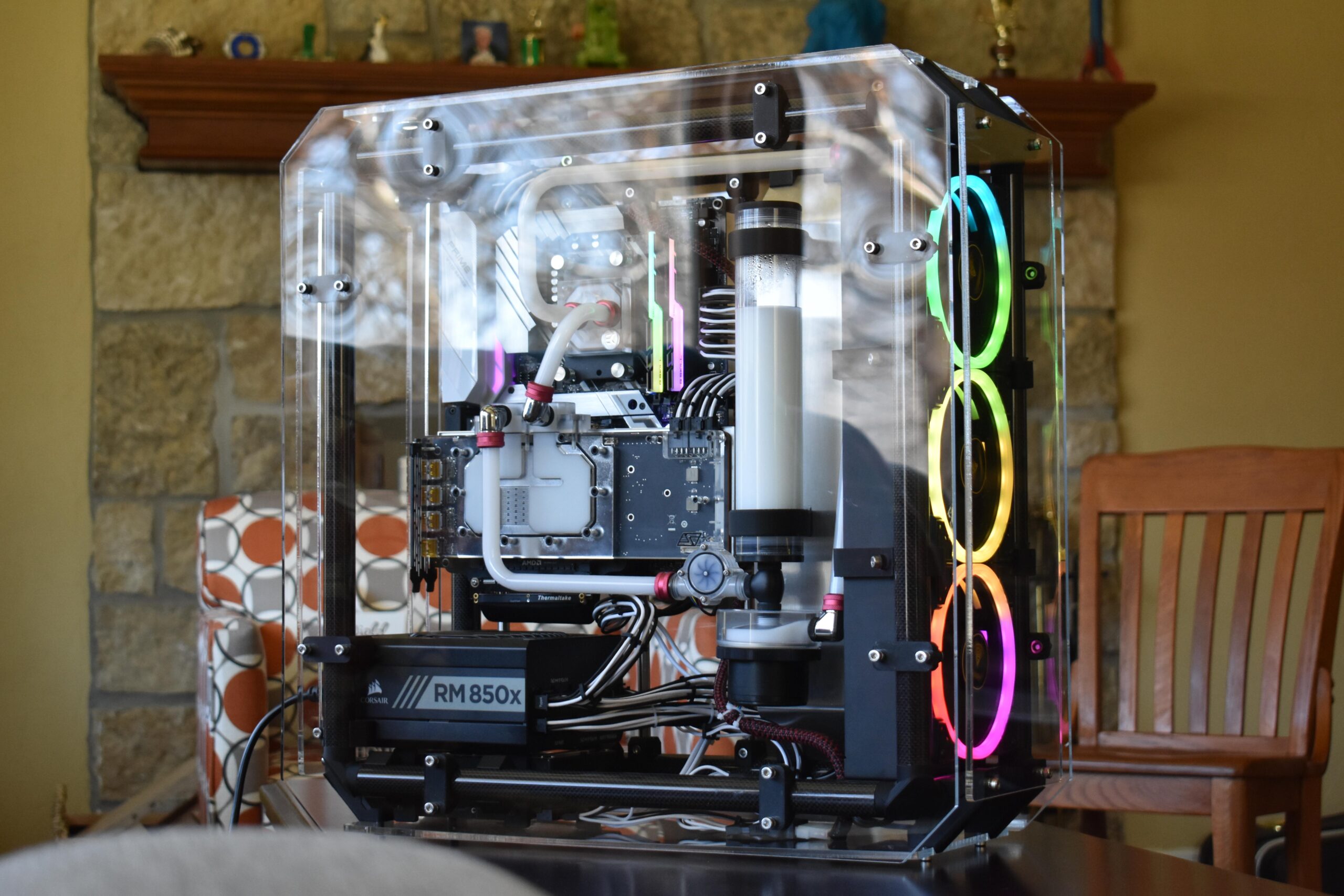

Custom PC building is a trend transforming computer enthusiasts into designers. This movement goes beyond off-the-shelf solutions. Hobbyists craft unique rigs, highlighting personality and performance. Suddenly, 3D printing PC cases becomes a canvas for creativity and tech prowess. Let’s explore this exciting evolution.

Personalization Meets Performance

Crafting a 3D printed PC case is the perfect blend of form and function. Enthusiasts can tweak every aspect:

- Aesthetic appeal – Choose colors, shapes, and sizes.

- Optimal airflow – Design for cooling efficiency.

- Unique components fit – Customize to exact hardware specifications.

These personalized cases are not just about looks. They boost performance by meeting specific cooling and spacing needs.

Evolving Hobbyist Culture

3D printing for PC cases signifies a shift in tech culture. Hobbyists now have tools to materialize visions once deemed impractical.

| Year | Change |

|---|---|

| Early 2000s | Limited to pre-made cases |

| Today | DIY 3D printed solutions |

Communities arise, sharing designs, techniques, and inspiration. It’s a global workshop, with 3D printing at its heart.

Credit: m.youtube.com

3d Printing: A Game-changer For Pc Enthusiasts

Imagine creating a custom PC case that’s tailored to your exact preferences. 3D printing empowers you to do just that, revolutionizing how PC enthusiasts design and build their dream machines. This technology turns intricate digital models into tangible, personalized PC cases. Let’s explore how 3D printing is altering the landscape of PC customization.

From Concept To Reality: The Design Process

Designing a 3D printed PC case begins with a vision. Your idea takes shape in a digital environment using advanced software. Consider features you want, like cooling vents or unique patterns. You can transform these concepts into 3D models ready for printing. It’s a seamless journey from imagination to a product you can touch.

- Sketch your initial concept.

- Use 3D modeling software to refine it.

- Prepare the model for 3D printing.

- Print a prototype to test for fit and function.

- Make adjustments as needed.

Material Selection For Optimal Durability

Selecting the right materials is crucial for durable, long-lasting PC cases. Various filaments offer unique benefits like strength, flexibility, and heat resistance.

Common choices include:

| Material | Properties |

|---|---|

| ABS | Heat-resistant and sturdy |

| PLA | Easy to print and biodegradable |

| PETG | Impact-resistant and flexible |

Consider the physical demands of a PC case. Your case needs to protect components and handle heat. Match your material to these requirements. A wise material choice extends the life of your case and PC parts. Aim for a balance between function and aesthetics

- ABS for heat-heavy builds.

- PLA for lighter, decorative cases.

- PETG for a mix of durability and flexibility.

Designing Your Own Pc Case

Designing Your Own PC Case opens a world of possibilities to PC enthusiasts. Imagine a PC case that perfectly fits your space, style, and system requirements. With 3D printing, that vision can become a reality. But before you dive into designing, two main areas demand your attention: optimizing airflow for cooling and balancing aesthetics with functionality.

Essential Considerations For Airflow And Cooling

Good airflow is the lifeline of every PC. It ensures that components remain cool and perform at their best. When designing your 3D printed PC case, consider these points to maximize airflow:

- Component Layout: Place heat-generating parts like the CPU and GPU where air can easily move around them.

- Fan Placement: Integrate spots for both intake and exhaust fans to create an effective air stream.

- Ventilation Holes: Add enough openings in your design to support the fans and avoid hot air getting trapped.

Aesthetic Versus Functional Design Choices

Choosing between a good-looking PC case and a functional one can be tricky.

| Aesthetics | Functionality |

|---|---|

| Unique shapes | Easy access to components |

| Custom paint jobs | Durable materials |

| LED lighting | Smart cable management |

Striking the right balance is key. Practical features will ensure your PC runs smoothly while personalized touches will make it uniquely yours.

The Printing Process

Imagine creating a PC case layer by layer right from your home. With 3D printing, that’s possible! The process turns a digital model into a tangible object. It involves precision, creativity, and a bit of technical know-how. Let’s dive into the details.

Layer By Layer: Understanding Fused Deposition Modeling

Fused Deposition Modeling (FDM) is a favorite for printing custom PC cases. First, a digital model splits into thin layers. Then, a printer heats plastic until it’s melty. It squirts the plastic out to make each layer. This stacks up to form the whole case.

- Design your model using CAD software.

- Choose your material, usually a type of plastic.

- Set the printer to follow the digital path.

- Watch as layers build one by one.

Post-printing Finishing Touches

Once the printer stops, your PC case isn’t done just yet. It needs finishing touches. Bits of plastic might stick out. They need trimming. Sand the case to make it smooth. Sometimes, you might want to paint it for a unique look. Or you might add some screws or clips to hold parts together.

- Remove the PC case from the print bed.

- Trim away extra bits with precision tools.

- Sand for a smooth, clean finish.

- Paint or decorate as you like.

- Assemble any additional parts or features.

Challenges And Solutions

Exploring the world of 3D printing offers endless possibilities, especially when crafting custom PC cases. Creative minds meet technical challenges, transforming ideas into tangible results. Addressing these challenges with innovative solutions is crucial for success in 3D printing PC cases.

Dealing With Structural Integrity Issues

Creating a durable PC case is a must. Structural integrity is key. Thin walls or weak joints can lead to breaks. Let’s explore ways to ensure your case is rock solid.

- Use higher infill settings to reinforce the print

- Choose the right material; something like PETG offers strength

- Design with geometry in mind – angles and curves can add strength

Implement these tips, and your 3D printed PC case will stand up to the test.

Overcoming Size Limitations Of Printers

Most printers have a build area that’s too small for a full-size PC case. But don’t let size limit your creativity. By splitting the design into parts, you can assemble a larger case post-printing.

- Segment your design into smaller, manageable pieces

- Ensure precision in measurements for a seamless fit

- Use strong adhesives or fasteners for assembling the parts

These solutions help turn your compact printer into a maker of mighty PC cases.

Credit: www.custompc.com

Related Articles

Mineral Oil PC Case: A Revolutionary Approach to PC Cooling

All in One Vs Desktop: The Ultimate Showdown in Power and Performance

7 Best Gaming Desktop under $1000

Community Contributions And Collaborations

The 3D printing space thrives on community contributions and collaborations. Enthusiasts and professionals alike create and modify PC case designs. These efforts push the boundaries of customization and function. This sharing culture nurtures innovation. Let’s explore how shared designs and collaborative projects are shaping the future of 3D printed PC cases.

Shared Designs And Mods: The Culture Of Sharing

The heartbeat of the 3D printing community is its readiness to share. Skilled designers upload their PC case blueprints online. Others download and modify them. Here are a few ways this culture manifests:

- Open-source platforms

- Design competitions

- Mod showcases on social media

- Feedback loops for design improvements

These actions empower hobbyists and experts to build upon each other’s work. They lead to a diverse range of PC cases, from compact designs to elaborate creations with integrated cooling systems.

Collaborative Projects And Their Impact On Innovation

When creators come together, they achieve what might be impossible alone. Collaborative projects in the 3D printing realm often result in groundbreaking innovations. Benefits include:

| Collaborative Aspect | Benefit |

|---|---|

| Cross-disciplinary expertise | Richer, more complex designs |

| Shared resources | Cost-effective solutions |

| Cumulative creativity | Innovative features and forms |

Such teamwork leads to remarkable PC case designs that may integrate advanced airflow, custom component fittings, or even sustainable materials. These projects inspire others and set new standards for what’s possible in 3D printing.

Frequently Asked Questions On 3d Printing Pc Case

Can You 3d Print A Pc Case?

Yes, 3D printing a PC case is feasible and has become increasingly popular among DIY enthusiasts. With the right 3D printer and materials, you can create a customized case that fits your personal needs and style preferences.

What Materials Are Best For 3d Printing Pc Cases?

ABS and PLA are widely used materials for 3D printing PC cases due to their strength and durability. ABS is more heat-resistant, making it suitable for components that may generate more heat, while PLA is easier to print with and comes in various colors.

How Much Does It Cost To 3d Print A Pc Case?

The cost of 3D printing a PC case can vary greatly depending on the size of the case, the material used, and the complexity of the design. Generally, you can expect to spend anywhere from $50 to several hundred dollars.

Is A 3d Printed Pc Case Safe To Use?

A 3D printed PC case can be safe if designed with proper ventilation and made from materials that can withstand the heat generated by PC components. Always monitor temperatures to ensure safe operation.

Conclusion

3D printing technology has revolutionized the way we create PC cases. Custom designs are now within reach, promising a perfect blend of form and function. Embrace the innovation and let your computer housing stand out. Remember, with 3D printing, your PC case can be as unique as your tech vision.

Ready to start printing?

I have read some good stuff here. Definitely value bookmarking for revisiting. I wonder how much effort you set to make one of these wonderful informative site.